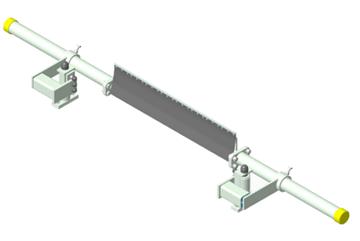

Polyurethane Blade-universal for splicing belt joint and mechanical joint.

Features l Highly effective cleaning performance l Long service life l Dynamic spring tension l Easy installation |  |

Application references

Applicable industries | Coal mines, power plants, steel mills, wharves, mines and cement plants. |

Suitable for material | coal, peeling soil, ore, aggregate and cement |

Suitable belt width | 650-2600MM |

Suitable for belt speed | 2.0-6.0m/s |

Suitable temperature | -30-70℃ |

Suitable temperature | -30-70℃ |

Tungsten Blade Cleaner- H Type-stuiable for splicing belt joint

Features • Highly effective cleaning performance • Long service life • Dynamic tension by cushion • Easy installation |  |

Application references

Applicable industries | Coal mines, power plants, steel mills, wharves, mines and cement plants. |

Suitable for material | coal, peeling soil, ore, aggregate and cement |

Suitable belt width | 900-2600MM |

Suitable for belt speed | 2.0-6.0m/s |

Suitable temperature | -30-70℃ |

Suitable temperature | -30-70℃ |

Antiwear offers two types of seondary cleaner with PU blade and Tungsten Tip separately.

Application • Highly effective cleaning performance via working with primary cleaner • Long service life • Easy installation |   |